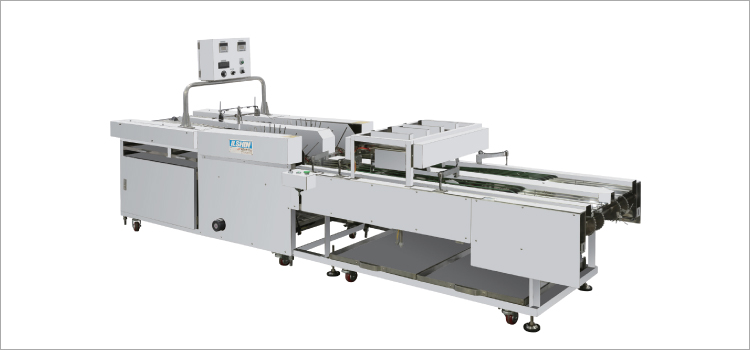

Model No.ILL-301

- SizeL1,250xW715xH1,200(m/m)

- Capacity70,000~100,000 sheet/8hour

- Power3P, 220~380V, 15kw

- Features· Supplies each sheet of the stacked laver to the parching machine.

· Automatic 2 rows supply system

· Used for regular-size laver and big-size laver